FAQ

Relating to Sales and Repair

- We would like to purchase your products, therefore, please advise us about your dealers and purchasing method.

- Contact your local sales distributors. Where to Buy

- Do you rent instruments?

- We do not rent our instruments.

- We would like to have our sensors (including sensors made by ALEC ELECTRONICS) repaired and calibrated. Who should we contact?

-

You can contact our sales team at the Ocean and River Instruments Division or your local distributors. Click Contact Form

Some products (such as those made by Alec Electronics) have been discontinued and cannot be serviced. Please refer to End-of-Sales Announcement and maintenance support of discontinued products.

About our products

INFINITY Series

- Can a commercially available miniSD card be used?

- The miniSD card used with INFINITY Series is an exclusive high-quality card. Therefore, a standard commercially available card may not work properly.

- Can we manually delete a file from the miniSD card of INFINITY Series while reading it on a PC?

- No. Although it is possible to read data from miniSD card, you should not delete a file directly. If you need to delete files from the miniSD card, insert the card on the instrument and make use of the dedicated software. If you already have deleted files directly. Please format the miniSD card. (use FAT32 format)

- How current direction on the INFINITY-EM is being reported? Is it the magnetic north used as reference?

- The current direction is direction where the flow is heading to and it is reported as the angle from the magnetic north (clockwise and with magnetic north being zero degree). Note that direction is not corrected to the true north.

RINKO-Profiler

- How fast can I set the profiling speed?

- Make sure you deploy the instrument with profiling speeds of 50 cm/s or less. This is because of the following reasons: 1. Sensors have different response times. If the profiling speed is too fast, the sensor response will not keep pace with the change of depth. Therefore, any high-accuracy measurement cannot be made. 2. If the deployment is being made with depth trigger mode set to be 0.1 m, and you are profiling the water at fast speeds, recorded data may not be synchronized. Consequently, data deviation may occur.

- Although, I used the depth trigger mode, why I got shallower depth than it supposed to be?

- Make sure you did not start profiling while the indicator LED was still flashing. Depth trigger mode will be zero depth automatically after 20 s of the instrument being turned ON. Only after that procedure, it will start recording data. The pilot lamp will flash until the instrument is ready to start recording data. If you deploy the sensor while the pilot lamp is still flashing, the instrument will not zero depth properly. Consequently, data will not be sampled from surface and will not be converted to meters properly. Therefore, make sure to only start profiling the water after the pilot lamp stop flashing.

- Downward and upward profile data obtained using time trigger mode are different.

- Consider downward data as correct. The instrument is designed to sample water properly while profiling the water downwards. Each sensor is placed in the lower portion of the instrument in order to measure the water column without disturbing it. The instrument will disturb the water when being pulled upwards. If you need to profile the water in the upward direction, stop the instrument at each desired depth for few minutes in order to get a stable condition.

- DO data is lower than it supposed to be.

- Make sure there is no oil attached to the DO sensor surface. Oil may prevent DO foil from direct contact with water. Clean the sensor surface with diluted neutral detergent in order to remove any oil from it. Do not use any kind of solvent, such as thinner, during cleaning.

- DO foil is damaged or peeled off.

- In such case, the DO sensor may not be sampling data properly. The DO foil must be replaced. If the sensing foil is dirty, wipe it off with a soft cloth gently. Do not use brushes or any hard material. Make sure not to damage the sensing foil while handling your instrument.

- Is it necessary to cover the DO sensor when not using it?

- Yes. The DO sensing foil is sensitive to light and you should protect it from light exposition by placing its protection cap while the sensor is not being used in order to reduce deterioration of the foil. Do not forget placing the protection cap on the DO sensor while it is not in use.

- How often do we need to replace the DO sensing foil?

- We recommend replacing it once a year. However, the deterioration of the foil depends on usage and exposition.

- For DO calibration, zero and span calibrations are required, but which one should be done first?

- For DO calibration in question, two solutions are required: 0% and 100% DO saturation solutions. The 100% saturated water is prepared by air bubbling and the anoxic water (0%) is prepared by using sodium sulfite. Perform the span calibration first to avoid contamination of the solution by sodium sulfite. After finishing span calibration perform zero calibration. This order will ensure a correct span calibration.

DEFI Series

- The instrument is not being recognized by the software.

-

Make sure that the infrared sensor is placed on the communication interface facing downwards.

Check if the battery inside the instrument is flat. After replacing the batteries, try transferring recorded data again.

- Data transfer stopped while transferring (incomplete data transfer)

-

Confirm if the instrument’s LED is lit while it is placed on the interface. If the LED is not lit, make sure that the battery has enough power and placed correctly. Also confirm if the sensor is placed correctly on the interface, with the infrared sensor facing downwards.

Make sure that the interface LED is lit when pushing the button “Read information” on the DEFI Series software. If the LED is not lit, you may need to install the interface driver onto your PC.

- Unable to clear memory

- Check if the battery inside the instrument is flat. After replacing the batteries, try cleaning the memory again.

- I cleared the memory, but when I tried to set an observation, a message asking me to clean the memory is being displayed.

- Check if the battery inside the instrument is flat. After replacing the batteries, try cleaning the memory again.

- I made a mistake on the density correction settings of DEFI-Dxx and DEFI-DxxHG / I made a mistake on the environment settings of DEFI-L.

-

You can generate a CSV file with the corrected values. Please check the manual for details in how to generate such file.

If you need to correct the RAW file. Please contact us.

- I cleared the memory before transferring my observation data.

- Observation data that has been cleared from the memory cannot be recovered. Make sure that you transfer all of your data before clearing the memory.

- The observation ended earlier than estimated due to battery run out.

- The battery life estimations written in the manual are an approximated and should be used as reference only. Battery life varies depending on the battery being used and the ambient temperature. In particular, if you use it at low or high temperatures, the battery will be consumed rapidly. We recommend using lithium batteries when observing in such conditions.

- Some sections of the observed data are missing.

- If an mechanical impact is applied to the instrument while it is observing data, data missing may occur. Make sure to securely fix the instrument while deploying it to avoid this kind of problem.

- There is a scratch or small damaged on the DEFI-T sensing head.

- Since the temperature sensor is embedded inside a titanium housing, even if the surface of the sensing head is scratched, it will not affect data quality. However, if the sensing head is dented or deformed, please contact us for further assessment.

- The holes in the sensor protection caps for DEFI-Dxx and DEFI-DxxHG are partially blocked.

- If at least one of the holes is free and not blocked, it will not affect data quality. However, if all the holes are blocked, data will be affected. Clean the protection cap as indicated in the instruction manual.

- There are scratches and dents on the pressure sensor surface of DEFI-Dxx and DEFI-DxxHG.

- Please contact us as the instrument may not be measuring properly.

- I used DEFI-L underwater, but data values are higher than expected.

- Even in water, DEFI-L data is converted to values as measured in air.

- The DEFI-L sensor is scratched or chipped.

- Please contact us as the instrument may not be measuring properly.

Software-related topics

- Is the current software use compatible with Windows7 or later?

- Almost all of our software are compatible with Windows7 or later. Always check if you have the latest software, as we always improve our products.

- Is the INFINITY Series software that we have, compatible with the latest models?

- Some versions of the software are not compatible with new models. Always check if you have the latest software, as we always improve our products.

- Can't we download the latest version software from your website? Can we download free of charge?

- Unfortunately, at the moment, we do not allow software download from our website.

- The INFINITY Series communication software, though installed on the PC, does not recognize the instrument correctly.

- After installing the software, make sure you install the INFINITY Series driver onto your PC. Follow the instructions in the manual in order to correctly install the INFINITY Driver. Or contact us if you have problems during installation.

Deployment-related topics

- We are planning a long-term observation using one of your loggers, for how long can we observe?

- There is a limit in the observation period due to battery and memory capacities. In the INFINITY Series, the maximum observation period can be approximately estimated by using the Acquisition Tools software. For other instruments, it can be calculated as specified in the instruction manual. You can also contact us at any time.

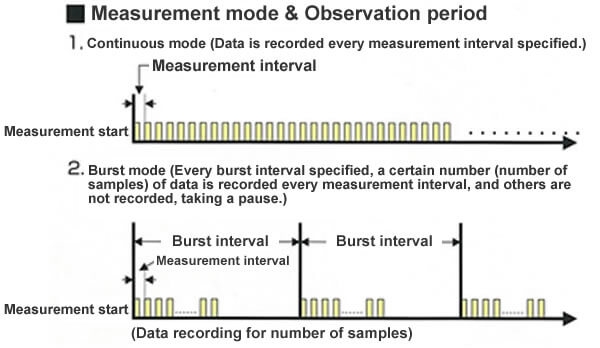

- We would like to know about the available observation modes for the INFINITY-Series.

-

Two modes are available: continuous mode and burst mode. More details on these modes can be found in the instruction manual or on the specification brochure.

General topics

- Before purchasing, we would like to test your instruments, is that possible?

- We have some instruments for demonstration and you can try them before purchasing. Please contact us for further details about these instruments.