What is Condition Monitoring System? :

This system enables to quantify the condition of machines in your facility and detect early signs of abnormality. Condition Monitoring System contributes to enhance capacity utilization, quality and saving cost for your maintenance and production activities.

Full support for design, installation and operation

We do full support from design, installation through operation by our long experience and reliable technology. We can propose the system to meet your requirements and machine conditions, including suggestion for numbers of sensors for local station and diagnosis software. Moreover, after installation, we continue to follow up for making your system efficiency.

Super

CMS-10000

The New World Classic - An Ever Evolving System -

We are proud of ”CMS series” and a large number of supply records.

Features

1. Automatic Diagnosis of rotating machines

Full-automatic system which analyses cause of abnormality and outputs reports.

2. Advanced analysis functions

Enhancement of vibration analysis function(FFT) by frequency analysis, up to max.51,200 lines which stand for 16 times our former model. It enables to detect early signs of abnormality precisely.

3. Expanded local station

Combination of most suitable units is available as requested.

4. Reatime vibration monitoring

Super CMS-10000 saves real-time vibration data of equipment in operation, and supports cause analysis of troubles and quality control.

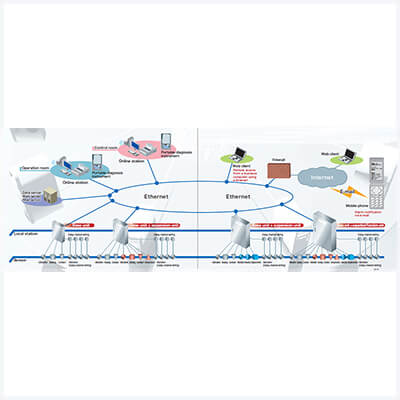

5. Data linkage function

Data communication is available between Super CMS-10000 and control equipment (DSC, PLC, etc.) through field network. Furthermore, it is easy to send CMS data and to import process signals.

6. Daisy chain function of vibration pickups

Vibration pickups can be wired with daisy chain system. Daisy chain wiring enables to reduce installation cost at site.

Compact Monitoring Unit

CU-10000 CU-20000

Easy installation, easy operation and low cost condition monitoring

Ideal for monitoring small-scale equipment, temporary installation and factories where equipment layout changes frequently, and similar situations

Features

1. Selectable 16 or 48 vibration sensors input

As other input signals, two types signals can be input. One is analog signal(rotating speed, temperature and etc.), the other is contact signal (operation / suspension). Various operation conditions can be seized. (Analog signal and contact signal can be chosen from 8 points or 40 points.)

2. Monitoring and/or setting on PC browser

Standard supported browser: Microsoft® Internet Explorer® Ver.8 to 11, Microsoft® Edge

3. Vibration waveforms are automatically collected to analyze cause of machine abnormality when vibration data exceed the threshold.

4. The unit has alarm contact output function as the standard. (Connection cable is available as an option.)

Alarm notification is sent by e-mail when the unit and mail server are used in one combination.

5. Collected data can be output in CSV file.

Data can be imported to our product "Vibration Diagnoser MAINTE PRO MK-220" software.

It easily makes precision diagnosis report.