KW-LU Series Belt Conveyor Scales

Belt Conveyor scales of load cells measure the weight of raw materials and products such as powders, grains, and lumps of transported by a belt conveyor.

- The compact structure has the whole system inside the conveyor frame.

- The rigid carrier reduces influence of elastic deformation from tension fluctuations.

- It is easy to install and maintain as there are no structures on the top or side of the conveyor belt.

- Weighing span can be adjusted by changing standard weight contained in standard configuration.

- The unit is equipped with a load cell protection device for operation under overload conditions.

- The frame has welded structure mainly made of shaped steel. It is designed to minimize strains with sufficient bending and torsional rigidity.

Load detection platform

Undermount weighing platform minimizes influence from of belt tension fluctuation and achieves high accuracy.

- The compact structure has the whole system installed inside the conveyor frame.

- The low displacement of the weighing carrier the small influence of fluctuations in belt tension fluctuations.

- It is easy to install and maintain as there are no structures on the top or side of the conveyor belt.

- The span is adjusted by changing the standard equipped check weight.

- The unit is equipped with a load cell protection device for operation under overload conditions.

- The frame is welded structure mainly made of shaped steel. It is designed to minimize the amount of strain with sufficient bending and torsional rigidity.

Specifications

| Platform name | LU-40 Type LUD-40 Type |

LU-120 Type LUD-120 Type |

LU-240 Type LUD-240 Type |

LU-450 Type LUD-450 Type |

|---|---|---|---|---|

| Measuring capability | ~40kg/m | 40~120kg/m | 120~240kg/m | 240~450kg/m |

| Belt width | 400~900mm | 750~1,200mm | 750~1,200mm | 900~1,800mm |

| Carrier pitch | 800~1,200mm | 800~1,200mm | 1,000~1,200mm | 800~1,200mm (LUD:1,000~1,200mm) |

| Load Cells | CBE1 type or CMM1 type | |||

| Accuracy | ±0.5~1.0% | |||

*The measurement capacity in the table should be a reference value and may differs slightly depending on the belt width and carrier pitch. We offer the most suitable load detection platform according to the measuring capacity of the conveyor, belt width, and carrier pitch.

* The LUD type has better accuracy due to its longer weigh length.

Standard model

| Belt width | 400 | 450 | 500 | 600 | 650 | 750 | 800 | 900 | 1,000 | 1,050 | 1,200 | 1,400 | 1,600 | 1,800 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LU-40 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||

| LU-120 | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||

| LU-240 | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||

| LU-450 | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

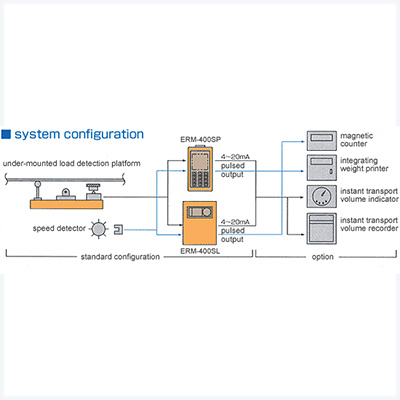

Integrator ERM-400SP

Excellent operability and automatic calibration function enables High-precision weighing

- Built-in zero adjustment and span setting function assists calibration operation.

- Applied power supply and reception amplification function for up to 4 load cells

- High-speed microcomputer enables all operations to be processed digitally and maintains high accuracy

Specification

| Item | Integrator | |

|---|---|---|

| ERM-400SP | ||

| Input | Load signal | Load cell excitation voltage DC0-20mV |

| Belt speed pulse | 0-120Hz duty ratio:30-70% | |

| Control signal | Hold Check OK Zero adjustment start Span adjustment start |

|

| Output | Load cell excitation voltage | DC10V, 120mA 350Ω 1-4 load cells |

| Instantaneous flow rate analog output Load rate analog output |

DC 4-20mA (less than or equal to load resistance 500Ω) DC 4-20mA (less than or equal to load resistance 500Ω) |

|

| Integrated pulse output | Semiconductor relay contact point Load capacity: Less than AC/DC 115 V 150 mA |

|

| Motor control signal | - | |

| Control signal | Checking Check complete Load rate : Upper limit, Lower limit Instantaneous flow rate: Upper limit, Lower limit Belt slip Abnormal, Normal |

|

| Display | Display element | Liquid crystal 128×128 dot |

| Character size | Height 8 mm × Width 4 mm (integrated value etc.) | |

| Displayed items during normal operation | Integrated value, Load rate, Instantaneous flow rate, Alarm, etc. | |

| Operation | Membrane switch 12 keys | |

| Power supply | 85~250 VAC、50/60Hz | |

| Power consumption | About maximum 50 W (at 100V) | |

| Operating environment | Temperature: -5 to 50°C, Humidity: 45 to 85% RH | |

| Integration accuracy | Linearity ± 0.05% F.S., Temperature coefficient 50ppm/℃ | |

Dimensions

Integrator ERM-400SL

Dustproof Waterproof integrator

- Built-in zero adjustment and span setting function assists calibration operation.

- Applied power supply and reception amplification function for up to 4 load cells.

- High-speed microcomputer enables all operations to be processed digitally and maintains high accuracy.

Specification

| Item | Integrator | |

|---|---|---|

| ERM-400SL | ||

| Input | Load signal | Load cell excitation voltage DC0-20mV |

| Belt speed pulse | 0-120Hz duty ratio:30-70% | |

| Control signal | Hold Check OK Zero adjustment start Span adjustment start |

|

| Output | Load cell excitation voltage | DC10 V, 120 mA 350 Ω 1-4 load cells |

| Instantaneous flow rate analog output Load rate analog output |

DC 4-20 mA (less than or equal to load resistance 500 Ω) DC 4-20 mA (less than or equal to load resistance 500 Ω) |

|

| Integrated pulse output | Semiconductor relay contact point Load capacity: Less than AC/DC 115 V 150 mA |

|

| Motor control signal | - | |

| Control signal | Checking Check complete Load rate : Upper limit, Lower limit Instantaneous flow rate: Upper limit, Lower limit Belt slip Abnormal, Normal |

|

| Display | Display element | Liquid crystal 128×128 dot |

| Character size | Height 8 mm× Width 4 mm (integrated value etc.) | |

| Displayed items during normal operation | Integrated value, Load rate, Instantaneous flow rate, Alarm ,etc. | |

| Operation | Membrane switch 12 keys | |

| Power supply | 85~250 VAC、50/60 Hz | |

| Power consumption | About maximum 50W (at 100V) | |

| Operating environment | Temperature : -5 to 50°C, Humidity : 45 to 85% RH | |

| Integration accuracy | Linearity ± 0.05% F.S., Temperature coefficient 50ppm/℃ | |

Dimensions (e.g. Installed in wall type panel)

Integrator ERM-500

5 inch sunlight readable TFT display.

- Graph display enables real-time confirmation of transportation status.

- Built-in Log function ,Read-write access to USB memory.

- Widely varying contact outputs can be set as desired.

Specifications

| Item | Integrator(ERM-500 SP/SL) | Integral Controller (ERM-500DP/DL) | |

|---|---|---|---|

| Input | Load signal | Load cell excitation voltage DC0 - 30mA | |

| Belt speed pulse | 0-400 Hz duty ratio:30-70% | ||

| Control signal |

Hold Check OK Zero adjustment start Span adjustment start Low speed operation Totalizer reset *Conditions apply. Sub totalizer reset *Conditions apply. |

(Left and the following signals can be input) Operation start Setting mode : Remote-setting Deviation reset Control output hold function |

|

| Output | Load cell excitation voltage | DC10V(at no load), 120mA 350Ω 1-4 load cells | |

| Integrated pulse output | Semiconductor relay contact point 2ch, Load capacity: Less than AC/DC 115 V 150 mA | ||

| Control signal |

(Output points :Standard 16 points, Option 4 points) Checking Check complete Check failure Normal Low speed operation Velocity detection Holding Load rate alarm : Upper limit, Lower limit Instantaneous flow rate alarm: Upper limit, Lower limit Belt slip, Upper speed limit Batch alarm |

(Left and the following signals can be input; Output points :Standard 16 points, Option 4 points) Run Deviation : Upper/ Lower/Upper Lower limits Setting mode : Auto/ Manual/ Remote-setting |

|

| Analog output |

DC 4-20 mA, Load resistance 500Ω or less Optional voltage output :Select from DC 0~10 V,DC 0~12 V,D C1~5 V,DC 1~10 V Available from standard 3points and option 1 point (Integrated value, Load rate, Zero adjustment amount, Belt speed pulse) |

DC 4-20 mA, Load resistance 500Ω or less Optional voltage output :Select from DC 0~10 V, DC 0~12 V,DC 1~5 V,DC 1~10 V Available from standard 3points and option 1 point (4 points can be input from left signals and Control output) |

|

| Display | Display element | 5 inch TFT display. 320×240 dot | |

| Displayed items during normal operation | Integrated value, Load rate, Flow rate, Belt speed, Moisture compensation , Alarm, etc. | ||

| Integration accuracy | Linearity ± 0.05% F.S., temperature coefficient 20 ppm/℃ | ||

| Operation | Membrane switch (sheet key) | ||

| Power supply | 85 ~ 264 VAC, 50/60 Hz | ||

| Power consumption | Maximum 10W (at 100V, Standard specifications ) | ||

| Operating environment | Temperature: -10 to 50°C, Humidity: 85% RH or less | ||

| Weight | SP type: Approx. 2 kg, SL type:Approx. 4 kg |

DP type: Approx. 2 kg, DL type:Approx. 4 kg |

|

Dimensions (e.g. Installed in wall type panel)